Modernisation of the Scharfenberg coupler type ZEa

The Electromechanical Apparatus Factory “FANINA” offers modernisation of front couplers type ZEa.

1. The modernised ZEa-FA automatic front coupler is used for:

- mechanical,

- electrical,

- pneumatic

connection of two units equipped with the same type of coupler without manual support.

2. Parameters of modernised front couplers:

- couplers of the same type are interchangeable,

- height of the coupler axis from the rail head level – 950+10-5 mm,

- allowable compression and tensile load – 1000 kN (100 t),

- load transferred by springs (elastomers) – 250 kN (25 t),

- pressure in the pneumatic system 0.5 –0.8 MN/m2 (5-8 kG/cm2).

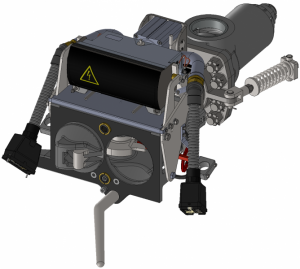

3. The modernised ZEa-FA coupler consists of three basic subassemblies:

- coupler head,

- coupler housing assembly,

- electrical coupler.

4. The renovation of the coupler head and housing assembly is carried out in accordance with the technology approved by the Transport Technical Supervision. The plant has CL1 certificate in accordance with PN-EN15085-2 and PN-EN ISO 3834-2.The repair involves restoring worn parts to their construction dimensions by hard-facing and heat treatment, considerably enhancing the

durability of renovated components. After consultation with the Customer, the components and parts, which are not eligible for renovation are replaced with new ones made according to the

original documentation. The components are controlled before treatment, during the renovation and after manufacture by the independent Quality Control in accordance with the quality

management system applicable in the plant pursuant to ISO 9001:2015. All materials used for renovation are certified. As a part of the coupler renovation, it is possible, after consultation with

the Customer, to install the coupler with elastomers instead of a set of ring and spiral springs.

5. The electrical coupler used in the modernised ZEa-FA coupler is a new device for automatic electrical connection of two electric trains. The electric coupler consists of a casing (moving in a

linear manner on guides and controlled actuator), inside which there is a panel with electrical contacts (the panel is available in different configurations) and wiring harnesses with plugs for

connecting the coupler to the unit.

6. The front panel is equipped with:

- set of Ø4mm gilded pins (male and female) for signals supplied over shielded cables,

- set of Ø4mm silvered pins (male and female) for signals supplied over single cables,

- module connector for Ethernet data transmission (minimum CAT5) 100Mbit/s with redundancy, equipped with gilded pins (male and female) for signals supplied over shielded cables.

7. All pins can be replaced from outside without the need of opening the coupler casing (the replacement of Ethernet pins is possible after the Ethernet module connector has been unscrewed from the front).

8. All cables are halogen-free cable with radiation cross-linked insulation.